- Keyword

Date:2018/08/24 hit:4325

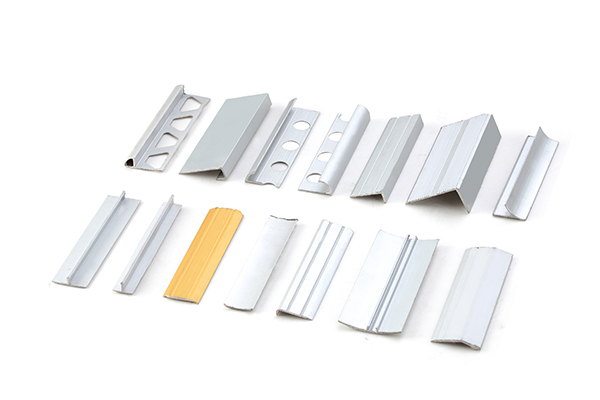

Scratch and scratch are the most common surface defects in the extrusion process of aluminum profile. There are rough longitudinal or transverse grooves and scratches on the surface of aluminum profile extrusion products. The scratches concave from the surface are mostly caused by foreign matters adhered to the mold or rough processing at the empty knife. There is also a raised scratch at the corner of the product, which is caused by the crack of the extrusion die. The transverse scratch or scratch is mainly caused by the scratch caused by the protruding hard object on the cooling bed when the product is transported from the sliding surface to the sawing table of the finished product. Some of the scratches are also caused during the loading and transportation. How to avoid scratches and scratches on aluminum profiles?

The main elimination methods are as follows

1) The working belt of extrusion die should be smooth, and the empty tool of extrusion die should also be smooth.

2) The mould should be checked carefully to prevent the mould with small cracks from being used. Attention should be paid to the fillet radius when designing the die.

3) Frequently check the cooling bed and finished product storage platform to prevent the products from being scratched by hard protrusions.

4) When loading, place a softer bar than the product. Transport and lifting should be smooth and careful.