- Keyword

Date:2018/04/01 hit:3038

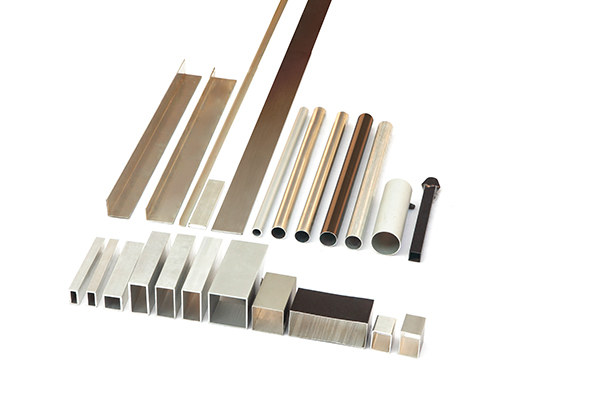

Aluminum profiles are aluminum materials with different cross-section shapes obtained by hot melting and extrusion of aluminum rods. The production process of aluminum profile mainly includes casting, extrusion and coloring. Then, the classification standards of aluminum profiles are as follows:

Classification method of aluminum profiles:

1、 Aluminum profiles are classified according to surface treatment requirements

1. Anodized aluminum

2. Electrophoretic coating of aluminum

3. Powder sprayed aluminum

4. Wood grain transfer printing aluminum

5. Planing aluminum (divided into mechanical planing and chemical polishing, of which chemical polishing is costly)

2、 Aluminum profiles can be divided into the following categories according to their uses:

1. Aluminum profiles for doors, windows and curtain walls

2. Special radiator aluminum profile for CPU radiator

3. The difference between them is the shape of cross section. But they are all produced by hot melt extrusion

4. Industrial aluminum profile: it is mainly used for automatic mechanical equipment, the framework of the cover, and customized mold opening by companies according to their own mechanical equipment requirements, such as assembly line conveyor belt, elevator, dispensing machine, testing equipment, etc. it is mostly used in electronic machinery industry and dust-free room.

3、 Aluminum profiles are classified according to alloy composition:

It can be divided into 1024, 2011, 6063, 6061, 6082, 7075 and other types of aluminum profiles. Among them, 6 series of aluminum profiles are common. The difference of different brands is that the proportion of various metal components is different. Except for the common aluminum profiles for doors and windows, such as 60 series, 70 series, 80 series, 90 series, curtain wall series and other building aluminum profiles, there is no clear model distinction for industrial aluminum profiles, Most of the production plants are processed according to the actual drawings of customers.